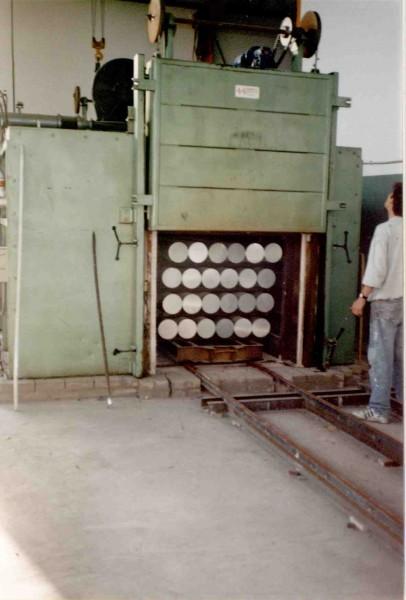

The furnace is very solidly built. It has an outline of steel sheet electrically welded on the outside and a stainless steel AISI sheet on the inside, thus forming a double wall filled with mineral fibres of high insulating quality and low weight, and as a consequence, low thermal inertia.

The load supporting carriages are entirely made of stainless steel.

The furnace insulation is made of a ceramic fibre layer, capable of resisting 850 degrees and a second layer that resists 550 degrees.

The rising and closing of the doors takes place thanks to closing flywheels that are manually activated.

Technical Data

| CHARACTERISTICS | |

|---|---|

| WORKING LENGTH | 4.000 – 6.000mm |

| CHARGING CAPACITY | 3.000 – 20.000Kg |

| WORKING TEMPERATURE | 575ºC |

| FURNACE MAX. TEMPERATURE | 650ºC |

| CYCLE TIME OF ENTIRE CHARGING | 4 – 12h |

| NUMBER OF BURNERS | 4 – 8 |

| SECURITY SYSTEM | Célula U.V. |

| FUEL | Propano o G.N. |

| BURNERS POWER | 100.000 – 200.000 kcal/c.u. |

| SWITCH ON | Automático |

| NUMBER OF ZONES FOR TEMPERATURE REGULATION | 2 – 3 |

| TEMPERATURE REGULATION SYSTEM | Proporcional – integral |

| TEMPERATURE PRECISION | +-3ºC |