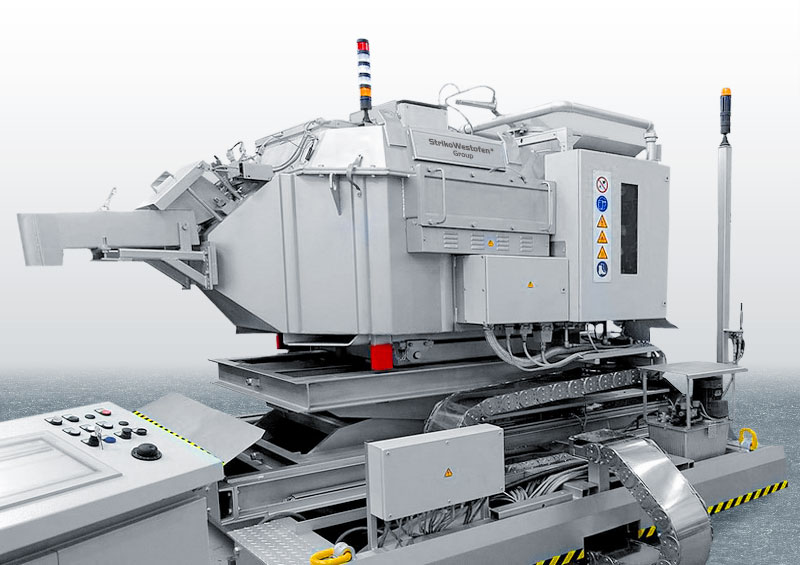

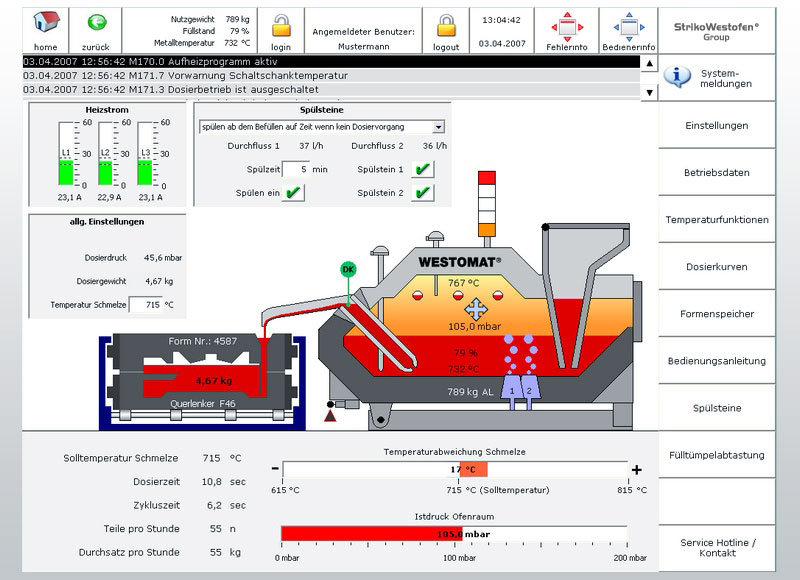

Dosificación para colada de gravedad y arena

- The Westomat® for gravity and sand casting provides maximum precision, excellent energy efficiency, high melt quality and maximum operating life. Special technical innovations also enable a significant increase in productivity during the manufacturing process.

Technical Data

| HIGHLIGHTS | |

|---|---|

| 1. | Sizes for all die-casting machines and casting capacities – 450 to 3100 kg. |

| 2. | Long refill intervals thanks to the high volume capacity |

| 3. | Easy integration in any die casting cell thanks to compact design and compatibility |

| 4. | Easy set-up of a casting program with Teach-In |

| 5. | Variable casting curve with up to five breakpoints per curve |

| 6. | High number of shape saving options |

| 7. | Easy adjustment of the casting weight by entering the data with the touch panel – no additional mechanical retooling necessary. |

| 8. | Freely programmable logic control (PLC) |

| 9. | Continuous dosing cycle even during refilling |

| 10. | High quality melt due to oxide-free metal removal below the level of the bath and constant metal temperature all the way to the metal casting chamber |

| 11. | Considerable increase in productivity of your casting cell thanks to Top-Stop-Position® |

| 12. | Energy-saving through use of high-quality insulating materials |

| 13. | Long service life of the refractory materials – many customers achieve more than 20 years. |

| 14. | Increase in the melt quality by optional use of the proven purge gas technology |