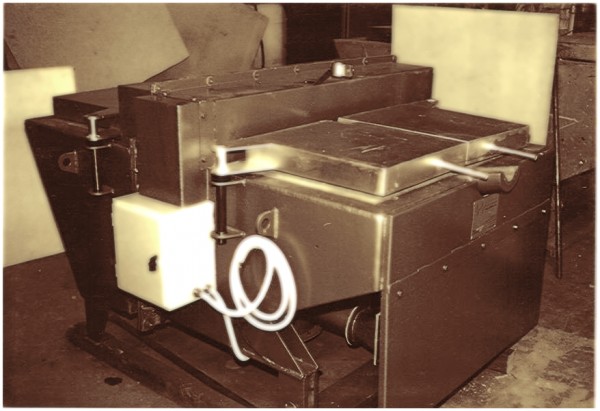

CHARACTERISTICS

- Air cooling.

- Temperature measuring directly in molten metal.

- Proteccion covers.

- Vertical position of the coil that avoids damages for metal penetration.

- High thermic insulation for higher efficiency.

- Accesible channel for cleaning and supervision.

- charging and extraction chambers independent.

CONTINUOUS CASTING APPLICATIONS

- HIGH efficiency for molten metal holding

- Homogeneous material thanks to the induction

- Refractory long lifetime

- Easy and quick change of dies in hot working because of hidraulic tilting.

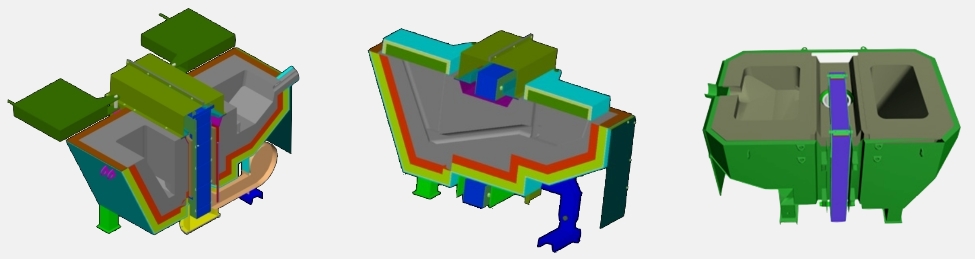

Technical Data

For die and inyection casting, and for continuous casting.

Technical Data

For die and inyection casting, and for continuous casting.

| FURNACE MODEL | CAPACITY | POWER (KW) | PRODUCTION (KG/H) | MELTING CONSUMPTION (KWH/KG) | DIMENSIONS(MM) | FURNACE WEIGHT (KG) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu. | Al. | BRASS | BRONZE | Al. | BRASS | BRONZE | Al. | WIDTH | LENGTH | HEIGHT | |||

| ROB1000 | 1.000 | 350 | 80 | 320 | 220 | 160 | 0,25 | 0,40 | 0,48 | 1.150 | 1.850 | 1.200 | 4.500 |

| 1.000 | 350 | 100 | 400 | 280 | 200 | 0,25 | 0,40 | 0,48 | 1.150 | 1.850 | 1.200 | 4.750 | |

| ROB2000 | 1.500 | 500 | 100 | 400 | 280 | 200 | 0,25 | 0,40 | 0,48 | 1.650 | 1.900 | 1.300 | 4.850 |

| 1.500 | 500 | 120 | 500 | 350 | 240 | 0,23 | 0,40 | 0,48 | 1.650 | 1.900 | 1.300 | 5.050 | |

| 1.500 | 500 | 150 | 600 | 400 | 300 | 0,20 | 0,38 | 0,45 | 1.650 | 1.900 | 1.300 | 5.350 | |